Through-hole / Mixed

State-of-the-art Contract Manufacturing

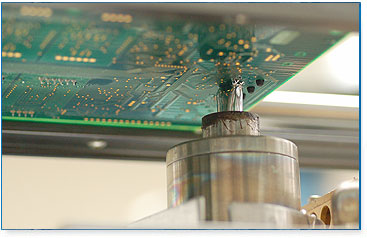

In order to decrease manufacturing time and costs, TL Industries has invested in a number of through-hole manufacturing equipment systems. This equipment includes axial lead insertion equipment, DIP IC Inserter and operator assisted through-hole insertion equipment.

In order to decrease manufacturing time and costs, TL Industries has invested in a number of through-hole manufacturing equipment systems. This equipment includes axial lead insertion equipment, DIP IC Inserter and operator assisted through-hole insertion equipment.

TL Industries has the technology necessary to manufacture products quickly, accurately and inexpensively while maintaining the flexibility to manufacture equipment with odd components or special requirements.

The automation area is the first stage for the printed circuit board assembly process. Surface mount, through-hole axial and DIP assembly processes are performed in this area. Once the printed circuit boards are processed through the automation area they are issued to the final assembly area, where operator assisted cut and clinch machines are used to install the odd form components before the wave soldering operation. After wave soldering, the assemblies receive any components that must be hand soldered, or select soldered with our automated soldering system, before they are forwarded to the Test Department for the specified test procedure.

The automation area is the first stage for the printed circuit board assembly process. Surface mount, through-hole axial and DIP assembly processes are performed in this area. Once the printed circuit boards are processed through the automation area they are issued to the final assembly area, where operator assisted cut and clinch machines are used to install the odd form components before the wave soldering operation. After wave soldering, the assemblies receive any components that must be hand soldered, or select soldered with our automated soldering system, before they are forwarded to the Test Department for the specified test procedure.

Once the manufacturing cycle is completed the assemblies are reviewed for conformance and are issued to the Shipping Department where they are shipped, according to the customer’s specifications

CONTACT US

........................................

2541 TRACY ROAD

TOLEDO, OHIO 43619

ph. 419-666-8144

fax 419-666-6534

E-MAIL: info@tlindustries.com